Our Products

Available Treatment

- Fresh Water Output: 1.5 tons per day

- System recovery rate : 12%

- Power Consumption : l .SKW

- Voltage: single-phase 220V/SOHZthree-phase 380V/SOHZ

- three-phase 440V/SOHZ

- Workingpressure: 35-SSMPA

- Operating temperature: 5-45°C

- lnlet water TDS: less than 40000PPM

- Desalination rate: 99.2%

- TDS: less than 700PPM

- Inlet PH value: 3-1O

- Size: 800mm*500mm*500mm

- Net weight: 100KG

- Packing net weight: 120KG

System Function

- Output Water Quality: Meet the national standard for drinking water <GB 5749-2006 >

- 0ver-pressure protection for the output water from high pressure pump, When the high pressure pump outlet pressure exceeds 6.Smpa, the equipment will stop automatically and show sound and light alarm.

- Under pressure protection when the inlet pressure of the high-pressure pump is When the water inlet pressure of the high-pressure pump is lower than O.OSmpa due to insufficient pre-treatment water supply, it will automatically stop and send an audible and visual alarm.

- Equipped with manual multi-way valve, the sand filter can be easily and quickly filtered, backwashed and forward washed as required.

- The alarm system is equipped with manual confirmation and sound elimination funcations

- Equipped with reverse osmosis membrane cleaning system, the reverse osmosis membrane components can be cleaned physically, replaced with concentrated water, cleaned chemically and injected with protective liquid.

Available Treatment

- Main features: small size, easy installation, convenient operation and

- Fresh Water Output: 3 tons per day

- Size: L * B * H = 500mm * 570mm * 1350mm

- Weight:::: 150kg (dry weight)

- Power Consumption : l .Skw

- System recovery rate:::: 15% (depending on temperature and water quality)

- Electric control protection grade: IP56

- Product color: primary color

- Material composition: SU5316 stainless steel

- Main accessories: high pressure pump adopts GIANT brand imported from the United States

- American Dow brand is selected as reverse osmosis membrane

- Effluent water quality: in accordance with GB5749-2006 drinking water quality standard

System Function

- Over-pressure protection for the output water from high pressure pump, When the high pressure pump outlet pressure exceeds 6.Smpa, the equipment will stop automatically and show sound and light alarm.

- Under pressure protection when the inlet pressure of the high-pressure pump is When the water inlet pressure of the high-pressure pump is lower than O.OSmpa due to insufficient pre-treatment water supply, it will automatically stop and send an audible and visual alarm.

- Equipped with manual multi-way valve, the sand filter can be easily and quickly filtered, backwashed and forward washed as

- The alarm system is equipped with manual confirmation and sound elimination

- Equipped with reverse osmosis membrane cleaning system, the reverse osmosis membrane components can be cleaned physically, replaced with concentrated water, cleaned chemically and injected with protective

Available Treatment

- Main features: compact structure, generous; Easy to

operate and maintain. - Fresh Water Output: 5 tons per day

- Size:L*B*H = 91 Omm*500mm*l 540mm

- Weight: ::::260Kg (dry weight)

- Power Consumption: 2.2 KW

- System recovery rate: ::::20% (depending on temperature

and water quality) - Power supply: AC380V / 50 Hz / 3 中

- Quality standard: comply with ship CCS inspection and

provide corresponding cert巾cate - Effluent quality: meet GB5749-2006 drinking water quality

standards - Electric protection grade: IP56

- Main components: high pressure pump imported from

- Italy original 316L stainless steel material;

- The reverse osmosis membrane is made by dow brand.

- Effectively ensure the core quality of products.

System Function

- Over-pressure protection for the output water from high pressure pump, when the outlet pressure of high pressure pump exceeds 6.SMPa, the equipment will automatically stop and give an audible and visual alarm.

- Under pressure protection when the inlet pressure of the high-pressure pump is insufficient. When the water inlet pressure of the high-pressure pump is lower than O.OSmpa due to insufficient pre-treatment water supply, it will automatically stop and send an audible and visual alarm.

- Equipped with manual multi-channel valve, the sand filter can be filtered, backwashed and directly flushed conveniently and quickly as required.

- The alarm system has the function of manual confirmation and silencing.

- Equipped with reverse osmosis membrane cleaning system, it can carry out physical cleaning, concentrated water replacement, chemical cleaning and filling of protective fluid for reverse osmosis membrane components.

Available Treatment

- Fresh Water Output: 1 O tons per day

- Size: L *B*H = l 520mm*800mm*l 920mm

- Weight: ::::SOOKg (dry weight)

- Power Consumption : 5.5 KW

- System recovery rate: ::::33% (depending on temperature

and water quality) - Power supply: AC380V / 50 Hz / 3 中

- Effluent water quality: in accordance with GB5749-2006 standard for drinking water quality

- Electric protection class: IP56

- Main components: high pressure pump is imported from

lta ly AR brand, 3 l 6L material - The reverse osmosis membrane is made by dow

System Function

- With touch screen human-machine interface, beautiful and generous, simple operation, operation and fault online display.

- 0utput Water Quality: Meet national drinking water standard < GB5749-2006 >

- 0ver-pressure protection for the output water from high pressure pump, When the high pressure pump outlet pressure exceeds 6.Smpa, the equipment will stop automatically and show sound and light alarm.

- Under pressure protection when the inlet pressure of the high-pressure pump is insufficient. When the water inlet pressure of the high-pressure pump is lower than O.OSmpa due to insufficient pre-treatment water supply, it will automatically stop and send an audible and visual alarm.

- Equipped with manual multi-channel valve, the sand filter can be filtered, backwashed and directly flushed conveniently and quickly as required.

- The alarm system has the function of manual confirmation and silencing.

- Equipped with reverse osmosis membrane cleaning system, it can carry out physical cleaning, concentrated water replacement, chemical cleaning and filling of protective fluid for reverse osmosis membrane components.

Available Treatment

- Fresh Water Output: 25 tons per day

- System recovery rate: 25%

- Power Consumption : 5.SKW

- Voltage: 440 V / 60 HZ

- Working pressure: 3.5-5.SMPAOperating temperature:

5-45°( - Inlet TD5: less than 40000PPM

- Desalination rate: 99.2%

- TDS: less than 700PP

- MPHvalue of inlet water:3-10

- Size: l 700mm*ll 20mm*l 900mm

- Packing spec巾cation (wooden case): 1900*1320*2100mm

- Net weight of equipment: SOOK

- Gpacking net weight: 880KG

System Function

- Output Water Quality: Meet national drinking water standard < GB5749-2006 >

- 0ver-pressure protection for the output water from high pressure pump, When the high pressure pump outlet pressure exceeds 6.Smpa, the equipment will stop automatically and show sound and light alarm.

- Under pressure protection when the inlet pressure of the high-pressure pump is insufficient. When the water inlet pressure of the high-pressure pump is lower than O.OSmpa due to insufficient pre-treatment water supply, it will automatically stop and send an audible and visual alarm.

- Equipped with manual multi-channel valve, the sand filter can be filtered, backwashed and directly flushed conveniently and quickly as required.

- The alarm system has the function of manual confirmation and silencing.

- Equipped with reverse osmosis membrane cleaning system, it can carry out physical cleaning, concentrated water replacement, chemical cleaning and filling of protective fluid for reverse osmosis membrane components.

Available Treatment

- Fresh Water Output: 60 tons per day

- Size: L * B * H = 2250mm * 1250mm * 2040mm

- Weight:::: 2500kg (dry weight)

- Power Consumption : 18.Skw

- System recovery rate:::: 33% (depending on temperature

and water quality) - Power supply: AC380V / SO Hz / 3 中,ac440v I 60Hz / 3 中,

ac480v I 60Hz / 3 中 - Effluent water quality: in line with GB5749-2006 drinking

water quality standard - Electric control protection grade: IP56

- Main components: the high-pressure pump is made of

sepck brand imported from Germany; the reverse osmosis

membrane is made of American ceramic Brand

System Function

- With touch screen human-machine interface, beautiful and generous, simple operation, operation and fault on line display.

- 0utput Water Quality: Meet national drinking water standard < GB5749-2006 >

- 0ver-pressure protection for the output water from high pressure pump, When the high pressure pump outlet pressure exceeds 6.Smpa, the equipment will stop automatically and show sound and light alarm.

- Under pressure protection when the inlet pressure of the high-pressure pump is insufficient. When the water inlet pressure of

the high-pressure pump is lower than O.OSmpa due to insufficient pre-treatment water supply, it will automatically stop and send an audible and visual alarm. - Equipped with manual or automatic multi-channel valve, the sand filter can be filtered, backwashed and directly flushed conveniently and quickly as required.

- The alarm system has the function of manual confirmation and silencing.

- Equipped with reverse osmosis membrane cleaning system, it can carry out physical cleaning, concentrated water replacement, chemical cleaning and filling of protective fluid for reverse osmosis membrane components.

Available Treatment

- Fresh Water Output: 100 tons per day

- Desalination rate: 99.2%

- System recovery rate: 35%

- TDS: less than 700PPM

- Power Consumption : 30KW

- PHvalue of inlet water:3-10

- Voltage: 380V/50HZ, 440V/60HZ, 480V/60HZ

- Size: S000*2000*1900mm

- Working pressure: 3.5-5.SMPA

- Packing spec巾cation (wooden case): 5400*2300*2200mm

- Operating temperature: 5-45°C

- Net weight of equipment:4SOOKG

- Inlet TDS: less than 40000PPM

- Packing net weight: 5000KG

System Function

- Output Water Quality: Meet national drinking water standard < GB5749-2006 >

- 0ver-pressure protection for the output water from high pressure pump, When the high pressure pump outlet pressure exceeds 6.Smpa, the equipment will stop automatically and show sound and light alarm.

- Under pressure protection when the inlet pressure of the high-pressure pump is insufficient. When the water inlet pressure of the high-pressure pump is lower than O.OSmpa due to insufficient pre-treatment water supply, it will automatically stop and send an audible and visual alarm.

- Equipped with manual multi-channel valve, the sand filter can be filtered, backwashed and directly flushed conveniently and quickly as required.

- The alarm system has the function of manual confirmation and silencing.

- Equipped with reverse osmosis membrane cleaning system, it can carry out physical cleaning, concentrated water replacement, chemical cleaning and filling of protective fluid for reverse osmosis membrane components.

JH-RO-75

Automatic direct drinking water system

Installation and operation instructions

Dear customer

Thank you for using our company’s pure water machine. Please read this installation and operation manual carefully before you install and use. You must pay attention to the following matters during installation and use.

- The main components of this machine are plastic Please often observe the integrity of the direct drinking machine during use to ensure safe use.

- Activated carbon powder also flushes out when the rear activated carbon filter element (t33) passes through the water for the first Therefore, do not open the water storage bucket within the first hour of the initial operation of the direct water dispenser. It is recommended to discharge the pure water produced during this period, otherwise the taste of the pure water will be abnormal.

- At the initial stage of operation, the TDS value of pure water may be After operation for a period of time, the TDS value of pure water gradually decreases to stable.

- When you use the water storage bucket for the first time, it is recommended to drain the first two buckets of water in the bucket, otherwise it may cause abnormal taste of pure

- The water produced by pure water mechanism is rich in oxygen, so the pure water produced will have many small bubbles, which is a normal

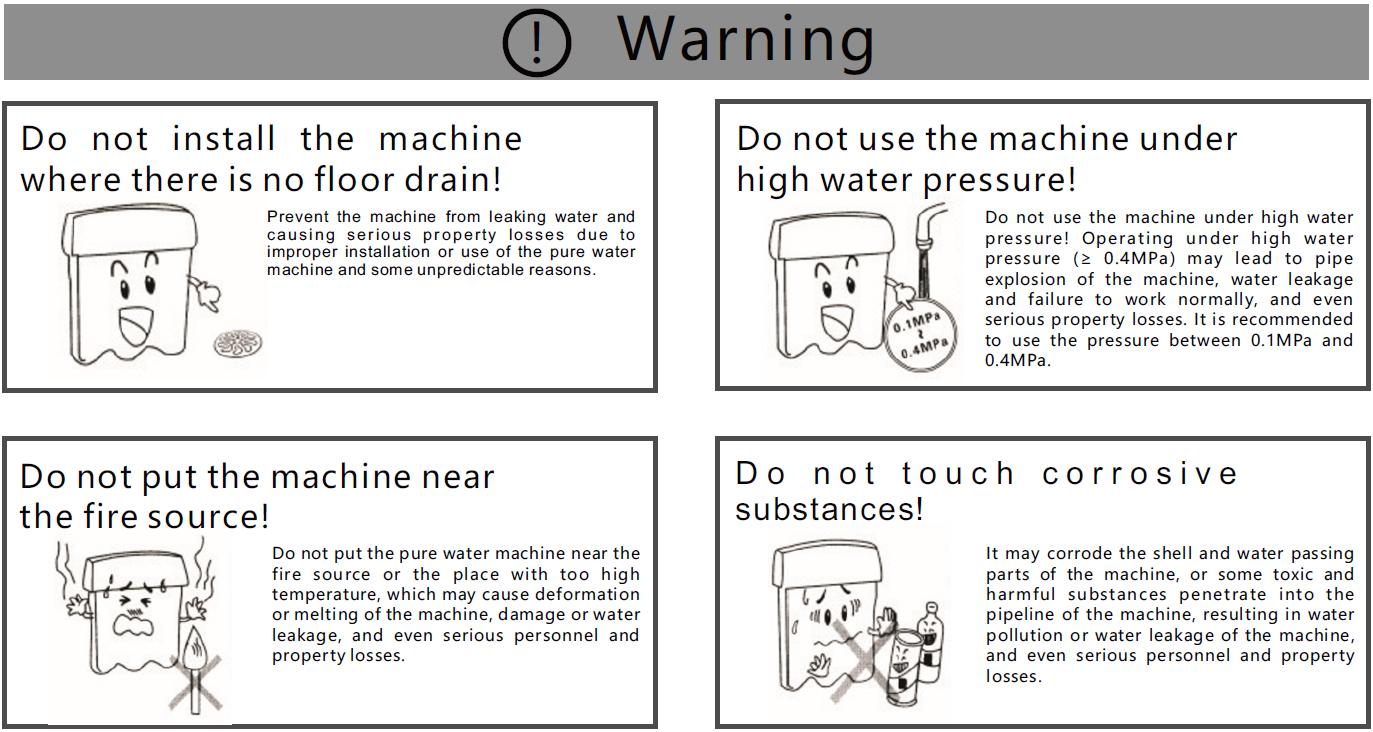

Safety precautions

Warning!!

Careful!!

(These safety precautions must be read and remembered)

In order to avoid possible injury or financial loss to you or others, please pay attention to the following safety precautions.

- The following signs indicate the degree of danger that may occur when ignoring the precautions of relevant personnel:

If the contents described in this sign are ignored, the pure water machine may be permanently damaged or damaged Causing serious property losses.

If the contents described in this sign are ignored, some parts of the pure water machine may be damaged or damaged Causing some property losses.

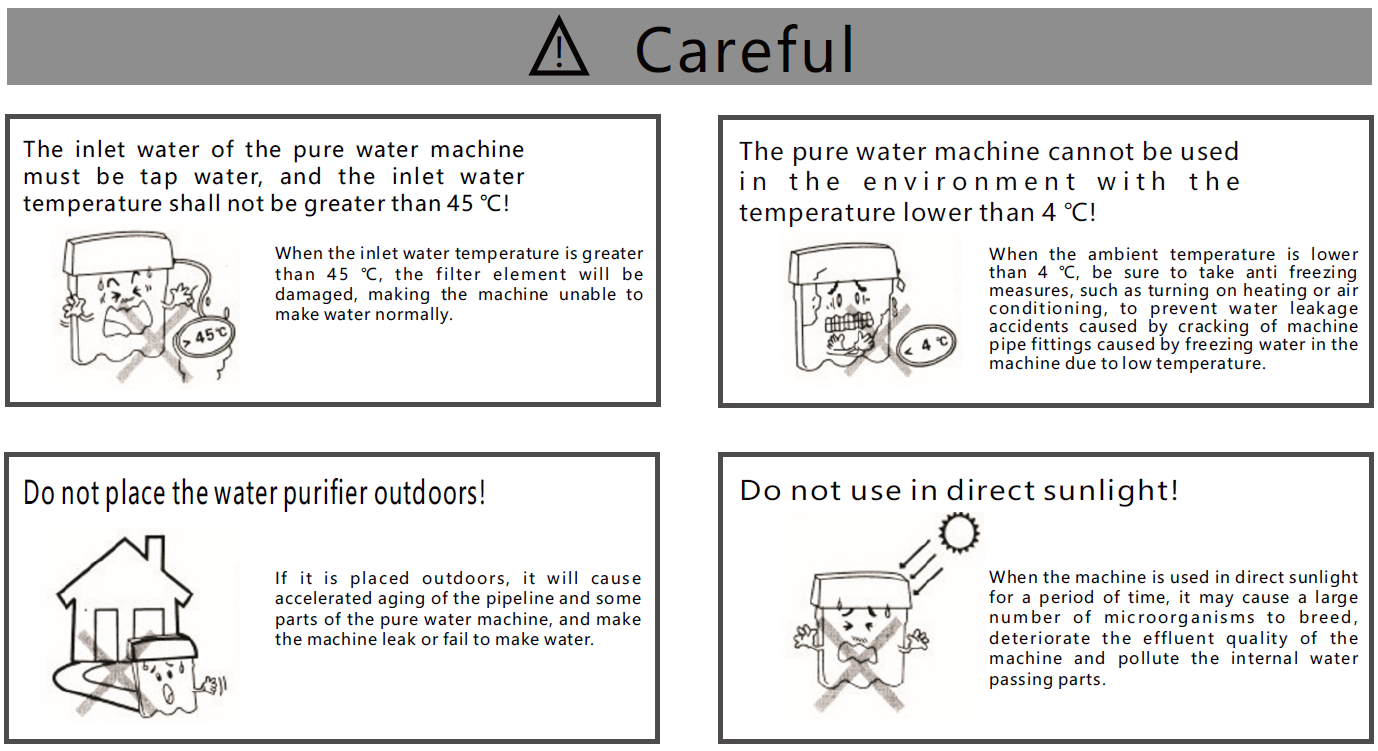

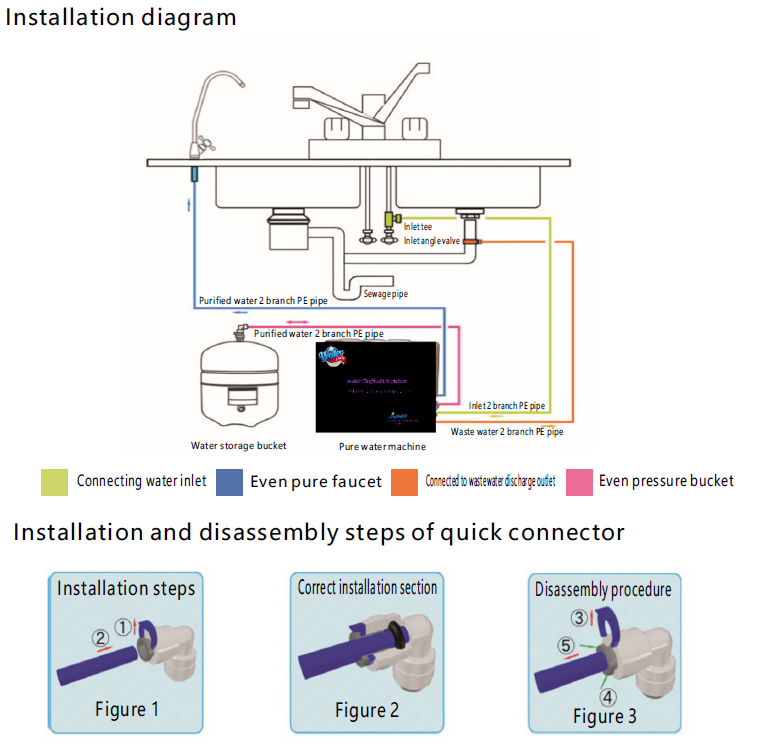

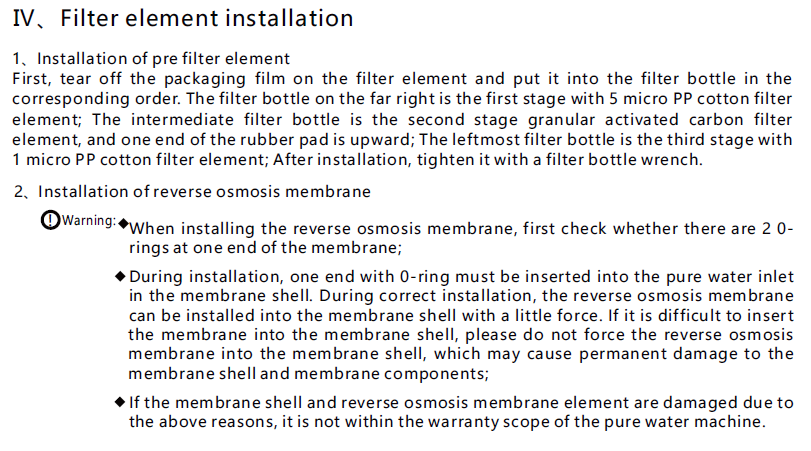

Installation Method

- Installation

- Cut the top of the pipe to be inserted vertically with a water pipe cutter or scissors

*The wall of the pipe to be inserted shall be smooth, clean and free of scratches

*If there are scratches, the pipes with scratches shall be cut vertically

- Remove the blue lock ring (see ① in Figure 1), insert the top of the cut pipe into the quick connector (see ② in Figure 1), insert it to the bottom with force, and then insert the blue lock ring (see Figure 2);

- The blue lock ring must be inserted at the quick connector collet to avoid during use The pipe was accidentally pulled out;

*Gently pull the collet out of the quick connector to make a gap between the two;

*Insert a blue locking ring between these gaps (see Figure 2)

- In order to verify whether the pipe connection is firm, pull the pipe with appropriate force,If the pipe cannot be pulled out:

- Wrap the raw material belt with appropriate thickness at the threaded quick connector thread, and then control one end of the quick connector thread with appropriate strength. Excessive force may screw the joint, and insufficient force may cause water leakage, so we must grasp the strength;

2. Dismantle

- First, check whether the water inlet pipe is closed to ensure that the water pressure is zero

- Remove the blue locking plate (see ③ in Figure 3):

- Hold the collet toward the quick connector with your index finger and thumb with one hand (see ④ in Figure 3),

Pull out the pipe with the other hand (see 5 in Figure 3).

Parts maintenance

Thank you again for using our company’s pure water machine. If you encounter difficulties in installation and use, please contact the local importer or machine sales organization, who will enthusiastically explain and debug or repair for you.

This installation and operation manual is for reference. In case of product upgrading or customization, the material object shall prevail, and the final interpretation right belongs to the company.